The original and the best!

Powder Coating for Alloy Wheels: Enhance the Look and Durability

Alloy wheel powder coating is a popular method used to enhance the appearance and durability of alloy wheels. This process involves applying a fine powder made of polymer resin and pigment particles onto the surface of the wheels, creating a protective and resilient coating.

This article will explore the benefits of alloy wheel powder coating, discuss the powder coating process, and provide helpful tips for maintenance and care.

|

In the following sections, we will delve into each aspect of the powder coating process for alloy wheels, providing valuable insights and step-by-step instructions. Additionally, we will explore popular colours and finishes, offer maintenance tips, and discuss the cost considerations associated with alloy wheel powder coating.

What is an alloy wheel powder coating?

Alloy wheels powder coating is a method of applying a durable, protective finish to alloy wheels. Powder coating involves applying a fine powder made of polymer resin and pigment particles onto the wheel surface. This powder is electrostatically charged and then fused onto the wheels through curing, creating a hard and resilient coating. (note we selected polyester powder for the wheels in this blog)

If you want to know more about Powder Coating, our website has a whole section, from articles and videos to general guides and instructions.

Benefits of Powder Coating Wheels

Alloy wheel powder coating offers numerous benefits over traditional painting methods or leaving the wheels bare. Let's explore some of its advantages:

- Enhanced Appearance and alloy wheel refurbishment: Powder coating provides a smooth, uniform finish that can transform the look of your wheels. With a wide range of colours and finishes, you can customise your wheels to match your vehicle's style.

- Increased Durability: The thick and resilient coating formed by powder coating helps protect the wheels from scratches, chips, and corrosion. Compared to standard paint, it provides better resistance to road debris, chemicals, and UV rays.

- Easy Maintenance: Powdercoated wheels are easier to clean and maintain. The coating's smooth surface makes it less prone to dirt and brake dust buildup, ensuring your wheels look great with minimal effort.

- Longevity: The durable nature of powder coating ensures that the finish lasts long. It can withstand the rigours of daily driving and maintain its vibrant appearance for years

The Powder Coating Process

Now, let's delve into the powder coating process and understand how powder coating alloys are achieved.

We often get asked if our powder coating system can powder coat wheels. As you would expect, the answer is yes, as this is one of the leading applications our customers use the powder coating system for. The next question is, must the wheels be returned to bare metal? This is where you have a choice with our system compared to the electrical systems on the market.

As always, good preparation is always the key. The best result is to take the wheel back to the base metal, repair the damage, and apply a primer prior to powder coating.

But ..... with our Easy Coat Powder Coating System, there is another option

Suppose the wheels you are refurbishing are in a reasonable condition with some slight damage or surface corrosion. In that case, you have the option with our Easy Coat powder coating system to prep the damaged/corroded areas and overcoat the whole wheel. The final durability of the powder coated wheel using this method ultimately relies upon how good the first coat of paint/powder coating is secured to the base metal, but if the original paint/powder on the wheel is in reasonable condition and secured to the base metal this method provides a much quicker and more accessible method of powder coating your wheels.

The following wheels we powder coated were approximately six years old and showed signs of surface corrosion. The finish on the wheels was a black wet paint finish with a clear coat of lacquer. Kerb damage was minimal, but where the diamond cut section was lacquered, it had corroded through and looked unsightly.

|

The following stages in this blog item will be covered

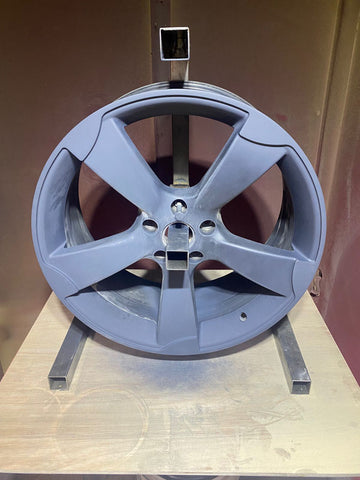

To this end, we made up a box section frame that facilitated mounting the wheel through one of the wheel bolt holes and provided an easy-to-carry handle for the movement of the wheel.

We have written an article on how to build your DIY POWDER COATING OVEN FOR £100.

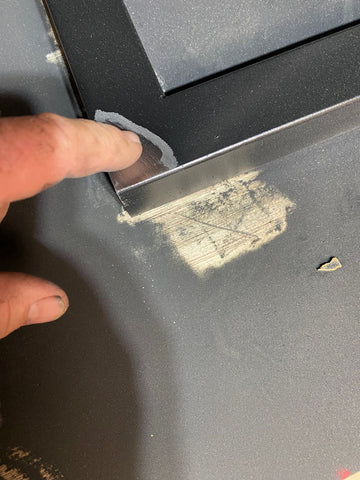

The existing paint then must be lightly flatted out with 250 grit paper, so any blebs or imperfections can be removed. This process of flatting will also act as a key and help the new powder adhere to the existing paint.

As part of the preparation stage, the valve also needs to be removed.

In our example, we cut the back of the valve off as we are fitting new valves to the wheel when the tyre is re-fitted. Also, any balancing weights and their adhesive need to be removed.

You need to do this with our system to ensure the neutralisation of the static. Note we sanded an area at the front and rear of the Jig to make it easy when spraying the front and back of the wheel. Next, set your gun up; this is best done by opening the regulator on the handle of your gun, closing off the regulator on your compressor, then holding the trigger of your gun in and gradually opening your compressor regulator to get a flow of powder out of the gun approximately 10" to 12". The gun is now set. Before starting the powder coating of the wheel give it a good blow down with an airline to remove any debris that has settled on the wheel.

Finally, because powder rests on large horizontal surfaces with no means of falling away with gravity, there is a risk that an excess of powder can rest in the lower section of the inside wheel rim. We overcame this by tipping the wheel back just over 45 deg in the Jig and allowing the excess powder will run out, thus leaving an even coating of powder in this area.

The issue with electrical systems being of a Corona charge design they do not perform well over coating parts and tend to exhibit inclusions in some areas when cured. We fixed this issue with our Easy Coat gun very easily by rubbing out the imperfections and re-coating the wheel.

There is a little more skill involved in powder coating this way as you could apply too much powder due to the excess powder not being able to fall away; however if you spray the part evenly and apply a similar amount of powder as if the part was cold you should not have a problem. When the part is fully coated this way, re-introduce it to the oven, raise the part to 180 deg c and hold it there for 10 minutes, then let it cool. We tested a small area on the wheels we powder coated for this article first to see if there would be a gassing out issue. We did this by prepping a small area, applying powder and curing it.

On these wheels, there was no gassing out issues present, thus we blended out this sample area and continued to complete the whole wheel. |

The final result finished in black satin.

Popular Colours and Finishes for Powder Coating Powders

When it comes to choosing colours and finishes for your alloy wheels, the options are practically endless. Powder coating allows for a wide variety of choices to match your personal style. Here are some popular colours and finishes you can consider:

- Glossy Colors: Classic shades like black, silver, white, and gunmetal are timeless choices that add sophistication to any vehicle.

- Metallic Finishes: Metallic powders create a shimmering effect, adding depth and dimension to your wheels. Colours like bronze, copper, and chrome are popular options.

- Matt Finishes: If you prefer a more understated look, matt finishes offer a sleek and modern appearance. Matte black and matte grey are trendy choices.

- Custom Colours: Powder coating also allows for custom colour matching like red candy, pearl top, slate blue, purple candy, burnt orange, and bright green, enabling you to create a unique look for your wheels that complements your car's overall aesthetics.

We have a broad range of powder coating powders available, including various colours and finishes. For example, adding a metallic top coat when overcoating a base colour can create a metallic or flip finish!

Maintenance and Care

Proper maintenance is essential to ensure the longevity and continued beauty of your powdercoated alloy wheels. Here are some tips for maintaining and caring for your powdercoated wheels:

- Regular Cleaning: Clean your wheels regularly using a mild soap or wheel cleaner and a soft brush or sponge. Avoid using abrasive materials or harsh chemicals that may damage the coating.

- Avoid Abrasive Cleaners: Avoid abrasive wheel cleaners or rough cleaning tools that can scratch the powder coating. Opt for gentle cleaning methods to preserve the finish.

- Protect from Road Hazards: Avoid driving over curbs, potholes, or rough surfaces that can cause impact damage to your wheels. Be cautious when parking to prevent scratches and dents.

- Winter Care: During winter, protect your wheels from road salt and harsh chemicals by applying a layer of wax or sealant. Regularly rinse off any salt or debris to prevent corrosion.

Cost Considerations

The cost of powder coated alloy wheels can vary depending on several factors, including the wheel size, the design's complexity and the desired finish. On average the cost of the powder to coat four wheels can range from £10 to £30 with our Powder Coating Kit, you can powder coat your wheels with the same professional finish that you would usually expect from the professionals -

You will need

- Our basic kit (current price £179.00).

- A compressor that produces 15 PSI and has a minimum of a 6 litre reservoir (expect to pay £100 or less).

- A heat source (see our blog and videos for some examples).

To sum up, powder coating your own wheels is fairly easy with a little practice and minimal skill. The costs involved can be much lower than powder coating specialists (costs can range between £500 to £1,000). The other benefits are that you control the quality and learn a new skill.

When completed, powder coated alloy wheels offer a range of benefits, including enhanced appearance, increased durability, easy maintenance and long-lasting finish. With its versatility and customisation options, powder coating allows individuals to transform the look of their wheels and protect them from damage. Whether opting for traditional colours or unique custom finishes, powder coating can enhance the aesthetics of any vehicle.

Proper maintenance and care are crucial for preserving the beauty and longevity of powder-coated wheels. With the availability of our DIY kits, you can now enjoy the benefits of professional-grade powder coating at a fraction of the cost. With its ability to enhance the look and durability of alloy wheels, powder coating remains a popular choice for automotive enthusiasts and those seeking to improve their vehicle's appearance.

Over the coming months, we will cover many other questions customers have asked us with a mixture of blog articles similar to this one and videos. If there are any particular areas you would like us to cover, please send us an email and we will try to cover it.

The other feature we built into this Jig was guide bars to the left and right of the Jig (the two legs on either side of the frame). The left to right dimension was slightly larger than the wheel diameter and smaller than the oven width. This provided protection against the side walls of the oven accidentally rubbing the powder off the wheel when putting in / taking out the wheel from the oven.

The other feature we built into this Jig was guide bars to the left and right of the Jig (the two legs on either side of the frame). The left to right dimension was slightly larger than the wheel diameter and smaller than the oven width. This provided protection against the side walls of the oven accidentally rubbing the powder off the wheel when putting in / taking out the wheel from the oven.